Melt Treatment Fluxes

For more than half a century, HOESCH has been developing melt treatment agents in the Dursalit ® product range. The cleaning and treatment of the molten aluminum is a decisive step towards the optimum quality of the melt. Thereby can non-metallic inclusions and interfering elements are removed, which can otherwise lead to casting defects and high scrap rates in production.

Each smelting process produces a slag with a high metal content. Special salt formulations are used to recover the valuable metal from the slag and separate it cleanly from the liquid metal. Thus, from a commercial as well as environmental point of view, the treatment of aluminum slag is a necessary step to improve production performance.

HOESCH Melt Treatment Fluxes are used worldwide in smelters, semi-finished product and remelting plants as well as mold foundries for light metal casting for covering, cleaning, degassing, gassing, grain refining , refining and slag treatment. HOESCH offers a special product range for heavy metal casting.

Product series

As powder, granules, fused fluxes or in tablet tablet form

- Recycling(DURSALIT® LA)

- Slag treatment(DURSALIT® LK)

- Cleaning(DURSALIT® LM)

- Removal of elements(DURSALIT® NaE, CaE, MgE)

- Degassing(DURSALIT® EGN)

- Fumigation(DURSALIT® LH)

- Grain refinement(DURSALIT® KFT, KFG)

- Sodium finishing(DURSALIT® LVE, LVG)

Other products for bronze, brass and zinc melts are available on request.

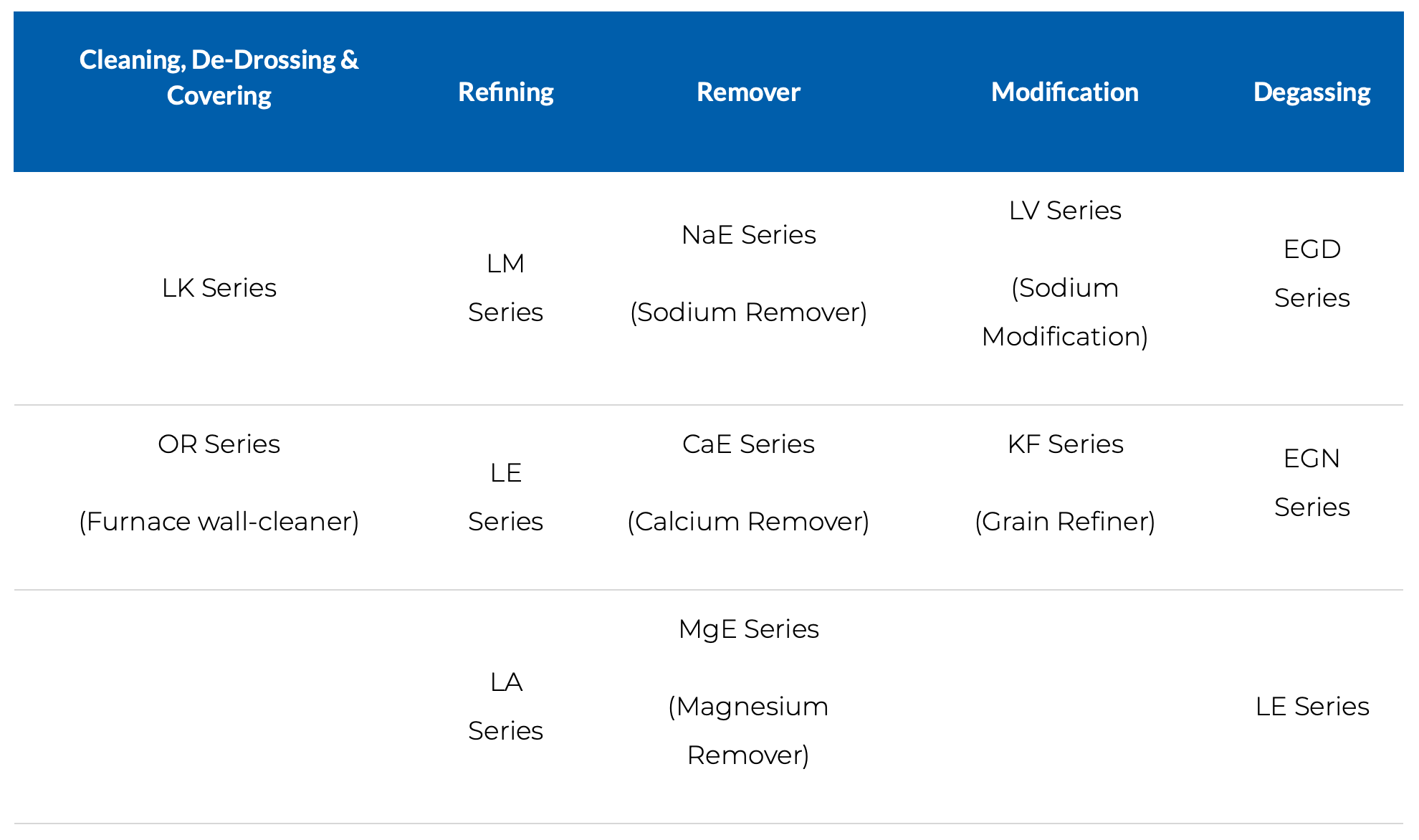

Our DURSALIT® product portfolio

|

Cleaning, De-throttling & Covering |

Refining | Remover | Modification | Degassing |

|---|---|---|---|---|

| LK Series | LM Series |

NaE Series (Sodium Remover) |

LV Series (Sodium Modification) |

EGD Series |

|

OR Series (Furnace wall-cleaner) |

LE Series |

CaE Series (Calcium Remover) |

KF Series (Grain Refiner) |

EGN Series |

| LA Series |

MgE Series (Magnesium Remover) |

LE Series |