Alloying Additives

Alloying elements

Iron

Manganese

Titanium

Copper

Chrome

HOESCH Alloying Additives are excellent products for alloying aluminum in smelters, semi-finished product and remelting plants, as well as in molding foundries. The addition of HOESCH alloying elements gives the aluminum produced the desired specific properties such as strength, formability, corrosion resistance or heat resistance.

HOESCH Alloying Additives are produced by powder metallurgy and are characterized by chemical purity and performance in the production of specific alloys. The high content of the alloying metal helps to reduce material, storage and energy costs and to achieve a high purity of the aluminum alloy. HOESCH Alloying Additives are thus the means of choice for a wide range of applications to optimize costs and product quality as well as to reduce CO2 emissions.

Our alloying additions are available in tablet or briquette form and are added directly to the melting or casting furnace. The composition of the individual alloying additions may vary depending on customer requirements. In addition to the main element, the residual components may consist of non-hydrous salts (flux), pure aluminum (Al), or a mixture of both.

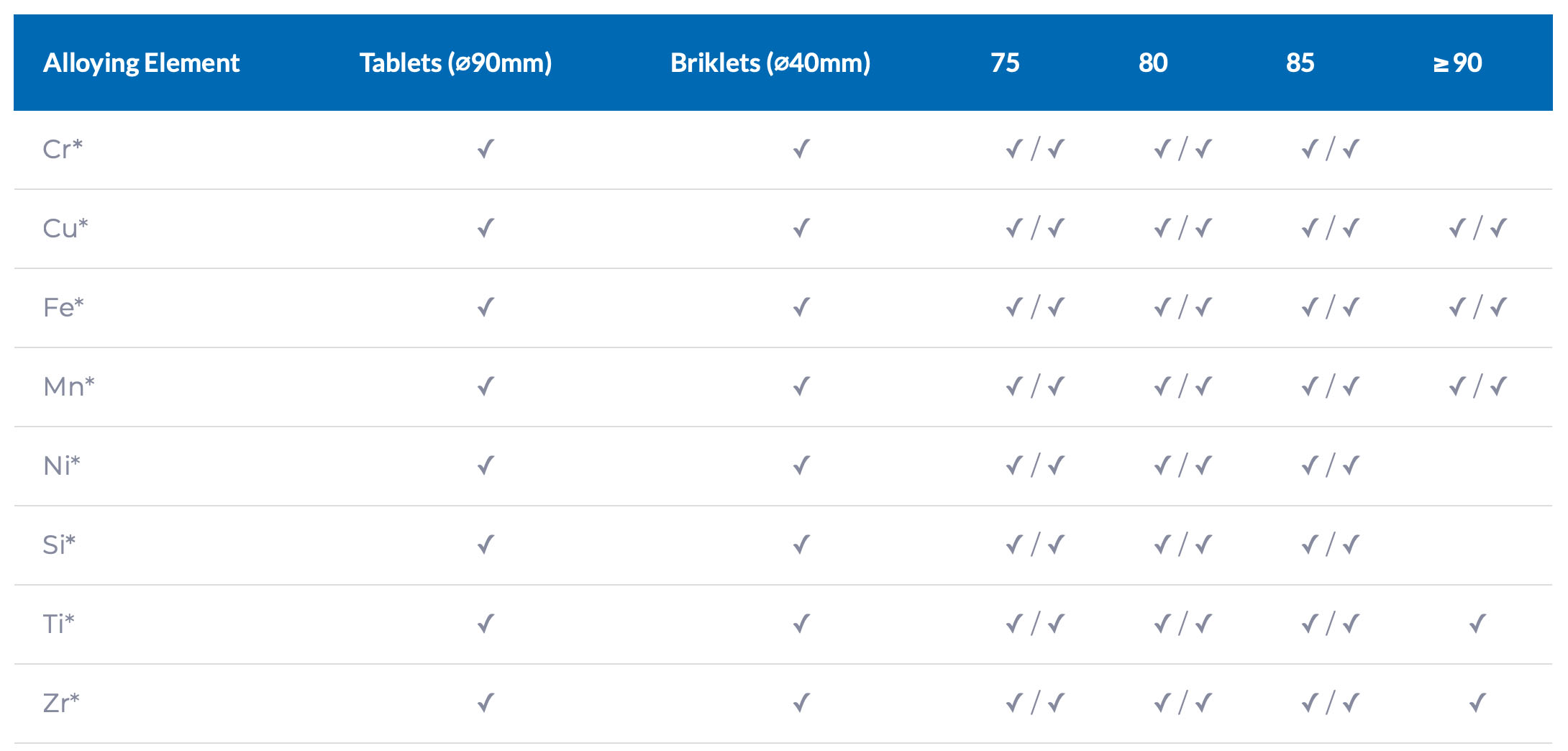

Our comprehensive product portfolio includes alloying elements in the following concentrations:

All products can be customized according to pressing density, diameter and weight.

* (with Al / with Flux)

Other alloying elements on request.

| Alloying element | Tablets (⌀90mm) | Briklets (⌀40mm) | 75 | 80 | 85 | ≥ 90 |

|---|---|---|---|---|---|---|

| Cr* | ✓ | ✓ | ✓ / ✓ | ✓ / ✓ | ✓ / ✓ | |

| Cu* | ✓ | ✓ | ✓ / ✓ | ✓ / ✓ | ✓ / ✓ | ✓ / ✓ |

| Fe* | ✓ | ✓ | ✓ / ✓ | ✓ / ✓ | ✓ / ✓ | ✓ / ✓ |

| Mn* | ✓ | ✓ | ✓ / ✓ | ✓ / ✓ | ✓ / ✓ | ✓ / ✓ |

| Ni* | ✓ | ✓ | ✓ / ✓ | ✓ / ✓ | ✓ / ✓ | |

| Si* | ✓ | ✓ | ✓ / ✓ | ✓ / ✓ | ✓ / ✓ | |

| Ti* | ✓ | ✓ | ✓ / ✓ | ✓ / ✓ | ✓ / ✓ | ✓ |

| Zr* | ✓ | ✓ | ✓ / ✓ | ✓ / ✓ | ✓ / ✓ | ✓ |

* (with aluminum and/or with flux)

Other alloying elements on request

Application examples

Application examples of aluminum alloys produced with the help of HOESCH Alloying Additives: